Standard Bowling Equipment Alley

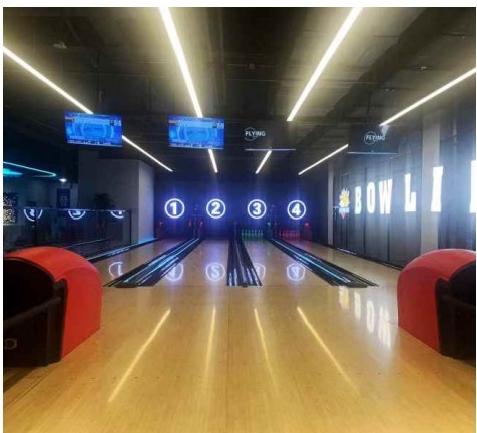

Bowling Alley Lane Basics

Bowling lanes are usually made of wood or synthetic materials, 60 feet long (about 18.29 meters) and 42 inches wide (about 1.07 meters). The entire lane is divided into several areas, including the track, the main lane and the groove area. The runway is located at the front of the track and is where the players prepare to throw the ball; the main track is the main area where the ball rolls; the groove area is located on both sides to prevent the ball from rolling off the track.

Equipment Lane Design and Maintenance

In order for the lane to provide the best playing conditions, both design and maintenance are very important. The surface of the lane must be specially treated to maintain the proper coefficient of friction, which determines the degree of rotation and sliding of the ball. The oil distribution of the lane is also a key factor. Different oil patterns will affect the trajectory of the ball, thus testing the technical level of the player.

Oil management of the lane

Oil management is an important skill in the game of bowling. By applying different amounts of oil to the lane, a variety of playing environments can be created, from easily controlled oil distribution to extremely challenging oil layouts.

Effect of Environmental Factors

In addition to the characteristics of the lane itself, environmental factors can also affect the results of the game. Changes in humidity can affect the friction coefficient of the lane, which in turn affects the performance of the ball.

The relationship between the lane and the ball

The shape, weight and hole layout of the bowling ball will affect its performance on the lane. A well-designed ball can produce the expected spin and arc on the lane, thereby increasing the chance of knocking down the pins.

Bowling is not only a contest of skill and strategy, but also of attention to and understanding of details. Standard bowling lanes are the foundation of the sport, and their design and maintenance are essential to providing a fair, fun and challenging competitive environment.